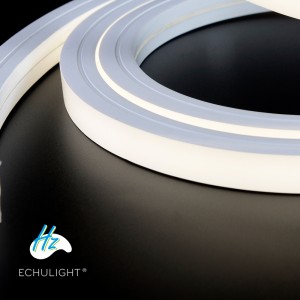

Stipriai šviečiantys, efektyvūs apvalūs 360° silikoniniai neoniniai šviestuvai

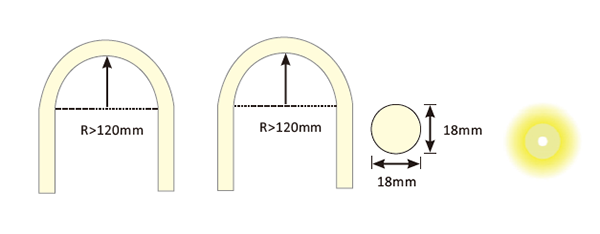

ECN-Ø18

ECN-Ø23

Gaminio apsaugos technologija ir konstrukcijos specifikacija

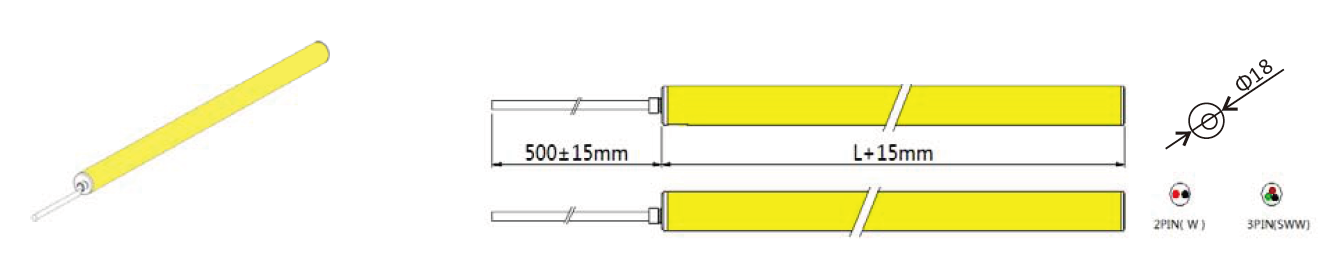

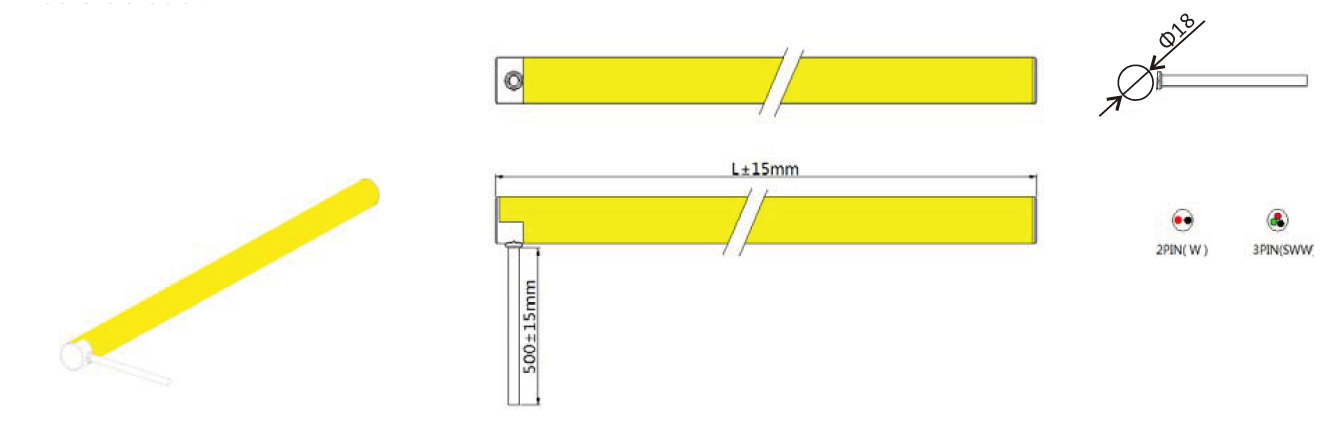

IP65 viršutinis lizdas

IP65 šoninis lizdas

Trumpas įvadas

Silikoninės neoninės LED juostelės savybės ir privalumai

A. Didelis pakeičiamumas

Silikoninės neoninės juostelės, pasižyminčios dideliu pakeičiamumu, visos neoninės juostelės gali pasiekti įvairius apšvietimo efektus, tokius kaip balta šviesa, RGB ir skaitmeninis atspalvis, gali pakeisti neoninį vamzdelį, apsauginių turėklų vamzdį, vaivorykštės vamzdį ir pan. .

B. Didelis šilumos laidumas

Didelis šilumos laidumas, silikono šilumos laidumas yra 0,27 W/MK, geresnis nei PVC medžiagos „0,14 W/MK“, o šviesos juosta pasižymi ilgesniu efektyviu šilumos išsklaidymu.

C. Atsparumas UV

Neoninės šviesos juostelės, pasižyminčios atsparumu UV spinduliams, ekstruzinis silikonas gali būti naudojamas lauko aplinkoje ilgalaikiam tiesioginių saulės spindulių poveikiui, ne pageltimui ir senėjimui virš 5 metų.

D. Antipirenas ir aplinką tausojantis

Neoninė juostelė yra aplinkai nekenksminga ir netoksiška, turi aukštą užsiliepsnojimo tašką, nedegi degant adata liepsna ir nedirgina nuodingų dujų, lakuojančių (ne kaip PVC), o tai yra saugesnė.

E. Atsparumas korozinėms dujoms

Neoninės LED juostelės yra atsparios korozinėms dujoms, įskaitant chlorą, sieros dioksidą, vandenilio sulfidą, azoto dioksidą ir pan.

F. Atsparus dulkėms

Venkite dulkių patekimo į neoninę juostelę ir pasižymi patikimu sandarumu, iki IP6X, gražia išvaizda, plačiu pritaikymo spektru ir ilgaamžiškumu.

G. Vienodas apšvietimas

Vienodas apšvietimas, be taškų, tiesioginio vaizdo paviršius, naudojamas labai atspindinčioms medžiagoms, pasižyminti blizgia aplinka, kurioje nėra akinimo.

H. Didelis šviesos pralaidumas

Neoninės šviesos juostos su dideliu šviesos pralaidumu iki 90%, gali atitikti didelio liumenų išėjimo reikalavimus ir yra naudojamos ne tik dekoravimui, bet ir apšvietimui.

I. Geras lankstumas

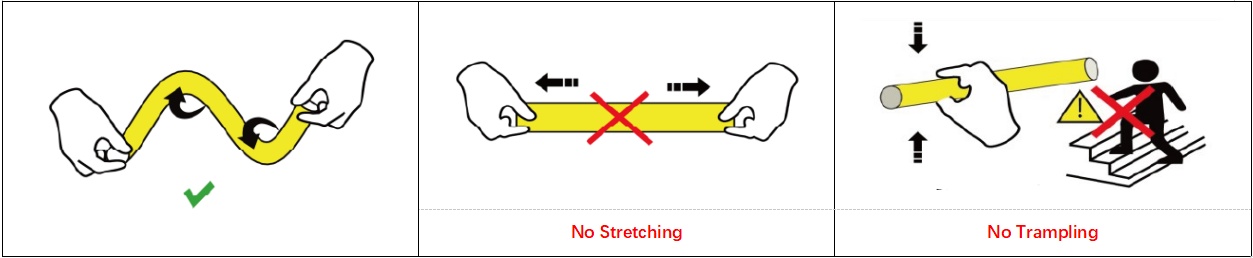

Patikima konstrukcija, pasižyminti geru lankstumu, naudojant tvirtą silikoną, pritaikyta vidinei struktūrai ir išorinei formai formuojant. Neoninė led juosta gali būti lankstoma ir susukama, tinka įvairioms formoms, atspari plyšimui ir tempimui, ją nėra lengva pažeisti ir deformuoti, esant geram lankstumui.

J. Išskirtinis atsparumas oro sąlygoms

Išskirtinis atsparumas oro sąlygoms, laikymas aplinkoje nuo -50 ℃ iki +150 ℃, neoninė juostelė gali išlaikyti normalią minkštą būseną, be trapumo, deformacijos, minkštėjimo ir senėjimo. O naudojant aplinkoje nuo -20 ℃ iki +45 ℃, neoninės LED juostos lemputės gali veikti normaliai, atsparios itin šalčiui ir dideliam karščiui.

K. Atsparumas korozijai

Neoninės šviesos juostos, pasižyminčios atsparumu korozijai, silikonas gali atsispirti įprastos druskos, šarmų ir rūgšties korozijai, gali būti naudojamos specialiose aplinkose, tokiose kaip paplūdimys, jachtos, chemijos pramonė, nafta, kasyklos ir laboratorijos.

L. Geros apsaugos savybės

Geros apsaugos savybės, pagrindinis neoninės LED juostos korpusas ir standartinis išleidimo angos dangtelis gali būti naudojami aplinkoje iki IP67 standarto ir gali atitikti IP68 laboratorinių bandymų standartus.

Pagrindiniai parametrai

| Modelis | CCT/spalva | CRI | Įvesties įtampa | Nominali srovė | Nominali galia | liumenas | Efektyvumas | Dydis | Maks. Ilgis |

| ECN-Ø18 (2835-336D-6 mm) | 2700 tūkst | >90 | 24V | 0.6 | 14.4 | 1267 m | 88 | Ø18 | 5000 mm |

| 3000 tūkst | 1267 m | 88 | |||||||

| 4000 tūkst | 1243 m | 85 | |||||||

| 6000 tūkst | 1295 m | 90 | |||||||

| ECN-Ø18-R/G/B (2835-120D-24V-6mm) | R: 620-630 nm | / | / | / | |||||

| G520-530nm | |||||||||

| B: 457-460 nm | |||||||||

| ECN-Ø18-SWW (2216-280D-6mm) | 3000 tūkst | >90 | 724 | 93 | |||||

| 5700 tūkst | >90 | 796 | 103 | ||||||

| 3000–5700 tūkst | >90 | 1475 m | 97 | ||||||

| Modelis | CCT/spalva | CRI | Įvesties įtampa | Nominali srovė | Nominali galia | liumenas | Efektyvumas | Dydis | Maks. Ilgis |

| ECN-Ø23 (2835-336D-6 mm) | 2700 tūkst | >90 | 24V | 0.6 | 14.4 | 1271 m | 86 | Ø23 | 5000 mm |

| 3000 tūkst | 1271 m | 86 | |||||||

| 4000 tūkst | 1271 m | 86 | |||||||

| 6000 tūkst | 1295 m | 90 | |||||||

| ECN-Ø23-R/G/B (2835-120D-24V-6mm) | R: 620-630 nm | / | / | / | |||||

| G520-530nm | |||||||||

| B: 457-460 nm | |||||||||

| ECN-Ø23-SWW (2216-280D-6mm) | 3000 tūkst | >90 | 718 | 93 | |||||

| 5700 tūkst | >90 | 783 | 100 | ||||||

| 3000–5700 tūkst | >90 | 1486 m | 97 |

Pastaba:

1. Aukščiau pateikti duomenys yra pagrįsti 1 metro standartinio gaminio bandymo rezultatais.

2. Išvesties duomenų galia ir liumenai gali būti keičiami iki ±10%.

3. Visi aukščiau pateikti parametrai yra tipinės reikšmės.

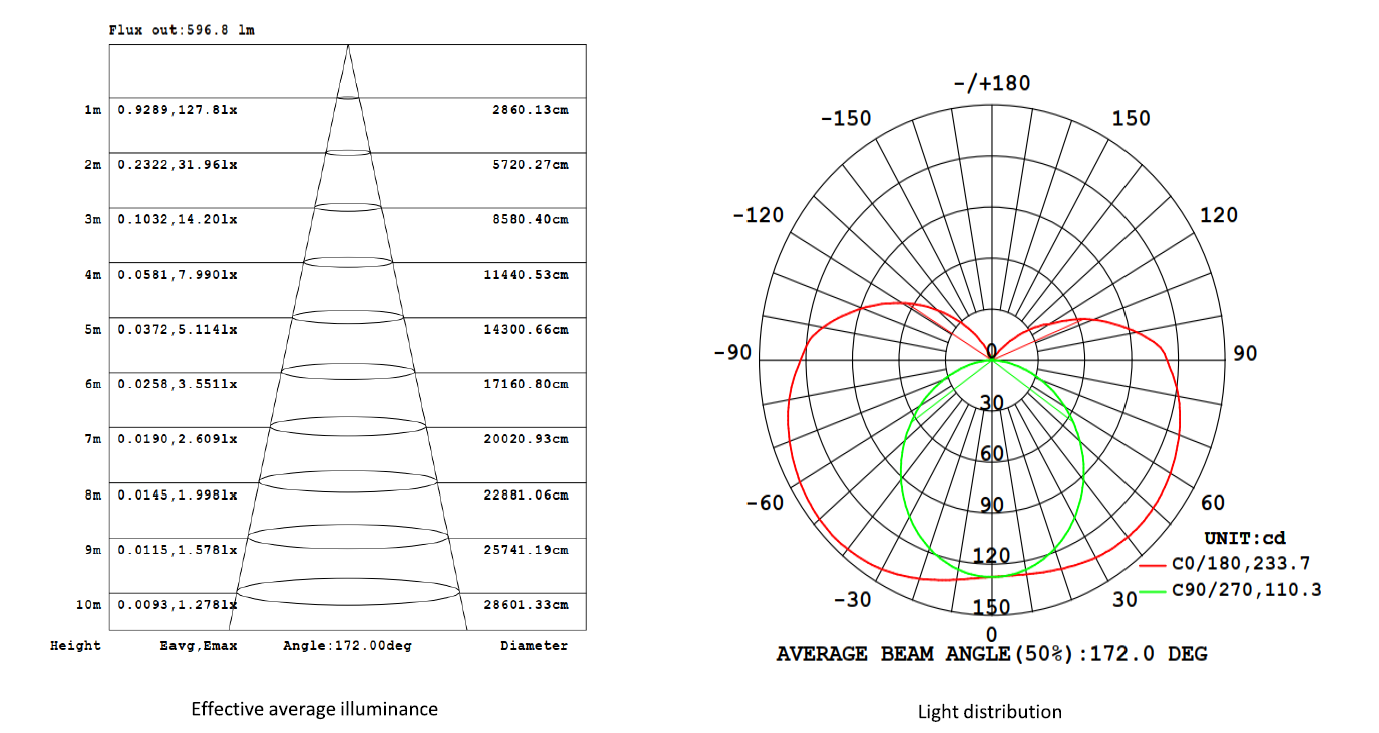

Šviesos paskirstymas

*Pastaba: aukščiau nurodyta data yra pagrįsta 4000K nespalvotos spalvos temperatūra.

CCT / spalvų parinktys

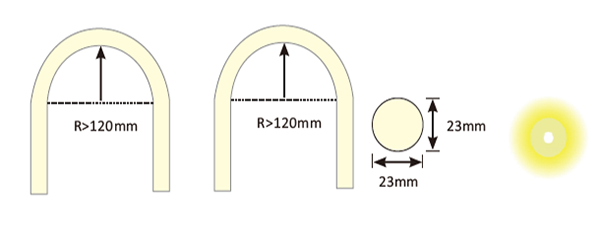

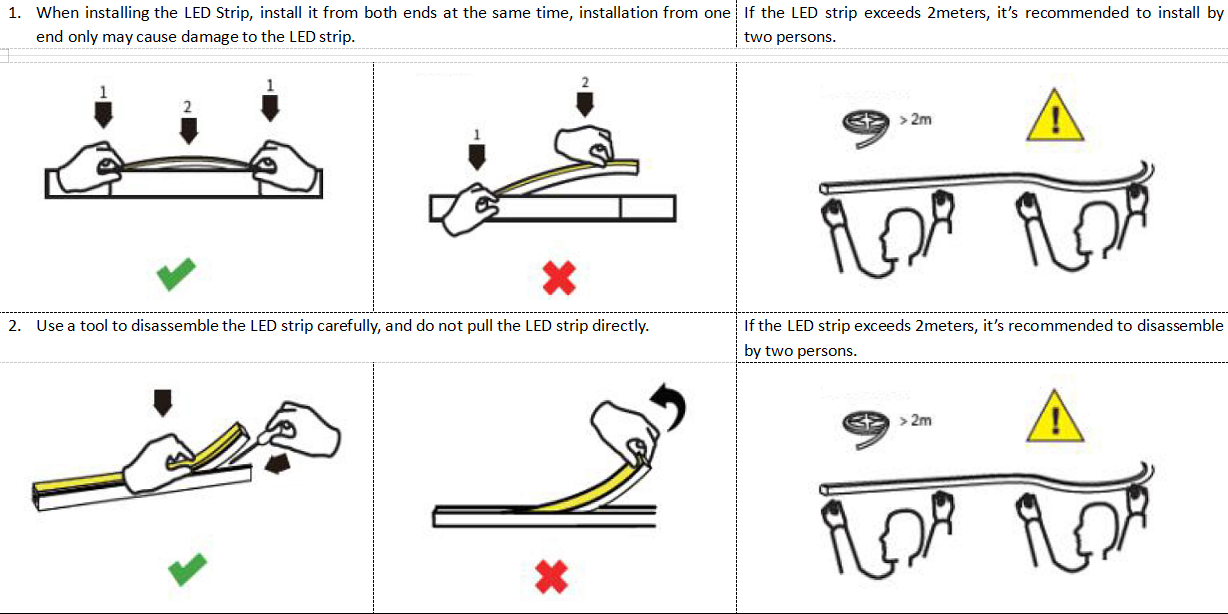

Montavimo instrukcijos

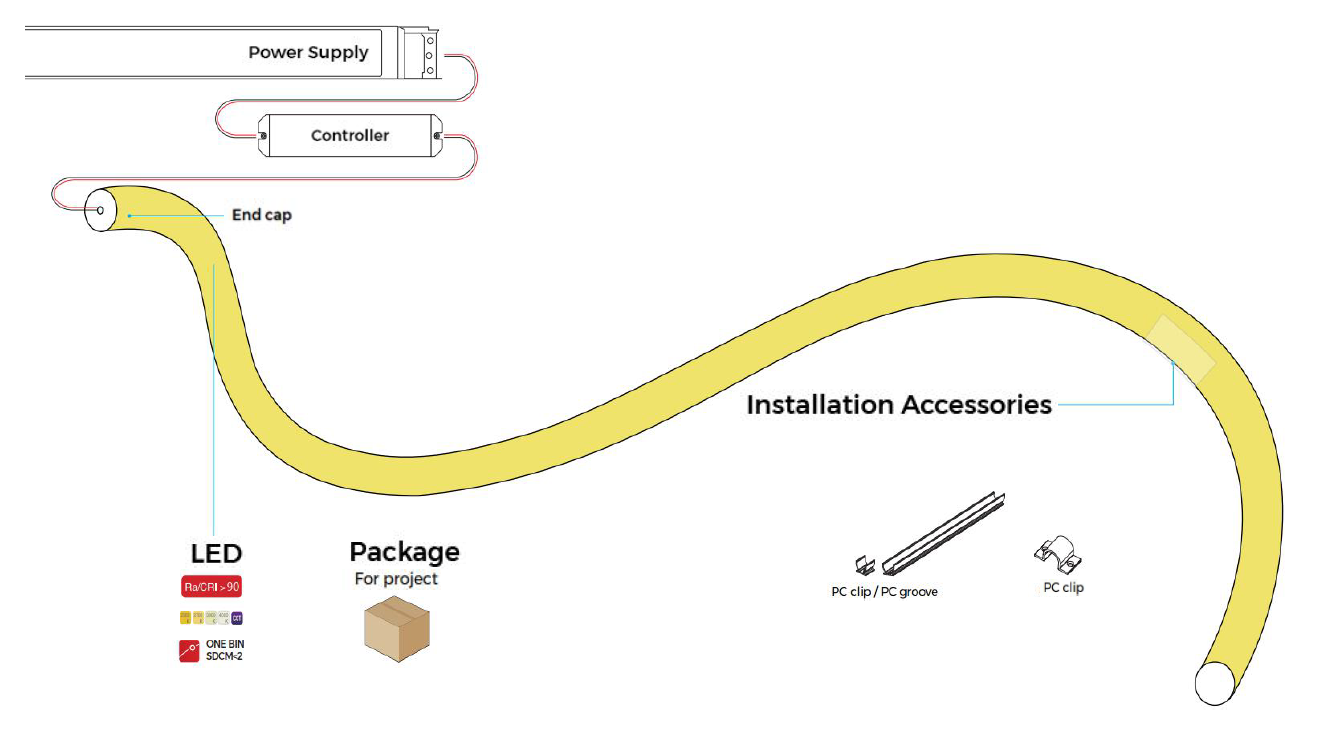

Sisteminiai sprendimai

Atsargumo priemonės

※ Šviesos diodų juostą naudokite reikiama izoliuota galia, o nuolatinės įtampos šaltinio pulsacija turi būti mažesnė nei 5%.

※ Nelenkite juostos į lanką, kurio skersmuo mažesnis nei 60 mm, kad užtikrintumėte ilgaamžiškumą ir patikimumą.

※ Nelankstykite, jei LED karoliukai pažeisti.

※ Netraukite stipriai maitinimo laido, kad užtikrintumėte ilgaamžiškumą. Bet koks susidūrimas gali sugadinti LED lemputę yra draudžiamas.

※ Įsitikinkite, kad laidas tinkamai prijungtas prie anodo ir katodo. Išėjimo galia turi atitikti juostos įtampą, kad būtų išvengta žalos.

※ LED lemputės turi būti laikomos sausoje, sandarioje aplinkoje. Išpakuokite tik prieš naudodami. Aplinkos temperatūra: -25 ℃ ~ 40 ℃.

Laikymo temperatūra: 0 ℃ ~ 60 ℃. Naudokite juosteles, kurios nėra atsparios vandeniui patalpose, kuriose drėgmė yra mažesnė nei 70%.

※ Būkite atsargūs dirbdami. Elektros smūgio atveju nelieskite kintamosios srovės maitinimo šaltinio.

※ Naudodami palikite bent 20 % maitinimo šaltinio, kad įsitikintumėte, jog energijos tiekimo pakanka gaminiui valdyti.

※ Nenaudokite rūgščių ar šarminių klijų gaminiui tvirtinti (pvz., stiklo cemento).

SusijęPRODUKTAI

-

Telefonas

-

paštas

-

Į viršų